Small Manufacturing ERP Software: Streamlining Operations for Small Manufacturers

Welcome to the world of small manufacturing ERP software where operations become more streamlined and efficient for small manufacturers. With the right software in place, small manufacturers can automate key processes, manage inventory effectively, and improve overall productivity. Say goodbye to manual tracking and disorganized systems, and say hello to a more structured and organized workflow. Let’s explore how small manufacturing ERP software can revolutionize the way small manufacturers operate and grow their businesses.

Overview of Small Manufacturing ERP Software

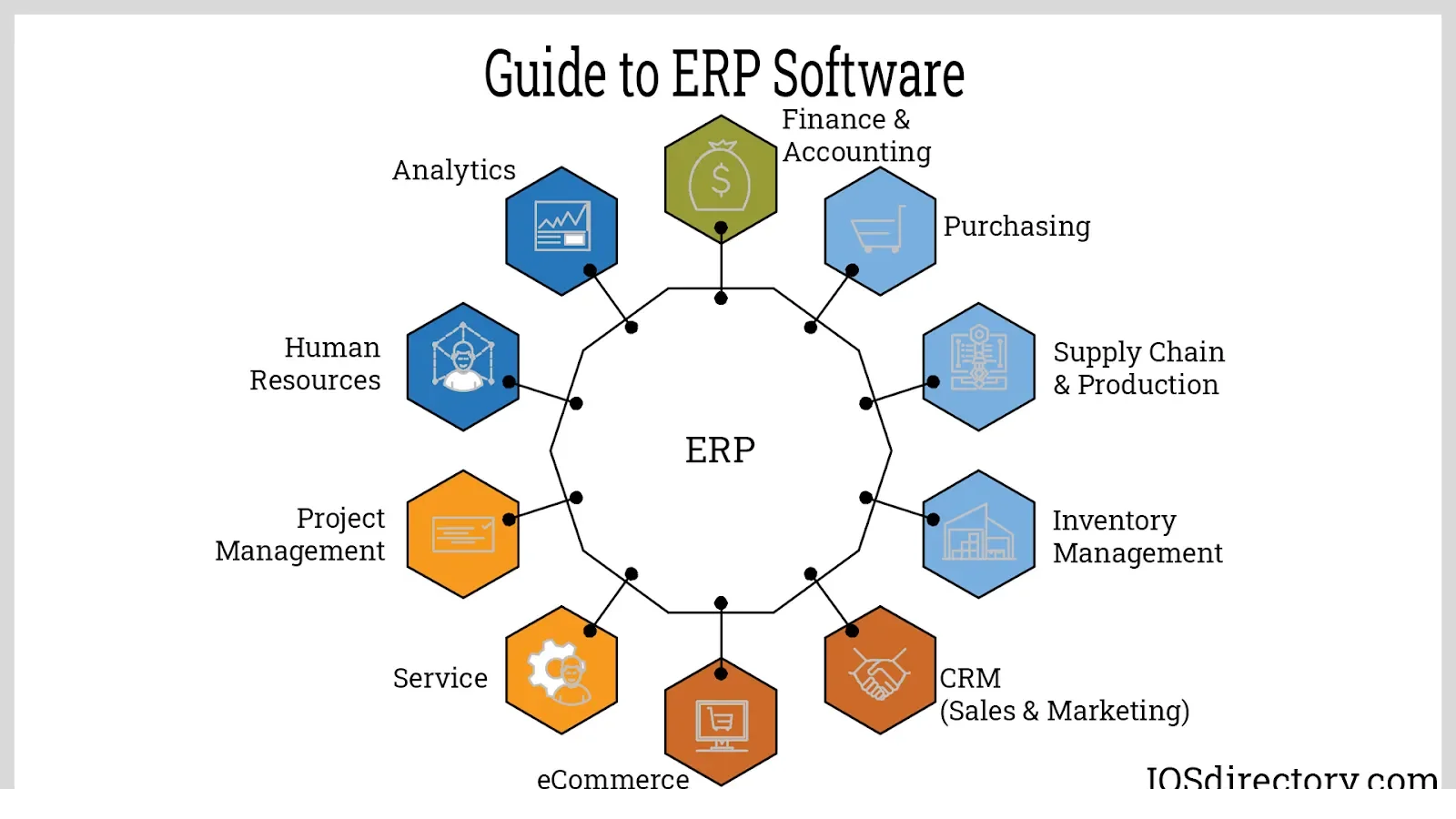

Small manufacturing ERP software is a specialized system designed to help small manufacturing businesses streamline their operations, increase efficiency, and improve overall productivity. This type of software is essential for small manufacturers who need to manage various aspects of their production process, including inventory management, scheduling, production planning, order tracking, quality control, and more.

Small manufacturing ERP software typically includes modules that cover the different functions within a manufacturing business, such as accounting, purchasing, supply chain management, customer relationship management, and production management. These modules are integrated to provide a comprehensive solution that allows small manufacturers to manage their operations effectively and make informed decisions based on real-time data.

One of the key benefits of small manufacturing ERP software is that it helps businesses automate manual processes, eliminate redundant tasks, and reduce the risk of errors. By centralizing data and providing a single source of truth, this software enables small manufacturers to track orders, inventory levels, and production schedules more efficiently, leading to better decision-making and improved customer satisfaction.

Moreover, small manufacturing ERP software provides visibility into every aspect of the production process, allowing businesses to identify bottlenecks, optimize resources, and improve overall efficiency. With features such as reporting and analytics, small manufacturers can monitor key performance indicators, generate detailed reports, and analyze trends to drive continuous improvement and innovation.

In addition, small manufacturing ERP software often includes advanced features such as barcode scanning, shop floor control, work-in-progress tracking, and lot traceability, which are essential for small manufacturers to meet industry regulations, maintain quality standards, and ensure compliance with customer requirements.

Overall, small manufacturing ERP software is a crucial tool for small manufacturers looking to compete in today’s fast-paced and competitive market. By investing in a robust ERP solution, small manufacturers can streamline their operations, optimize production processes, and enhance their overall business performance.

Key Features and Functions for Small Manufacturers

Small manufacturers often have unique needs and challenges that require a specialized ERP software solution. Here are some key features and functions that are essential for small manufacturers:

1. Inventory Management: Small manufacturers need to efficiently manage their inventory to ensure they have the right amount of raw materials and finished goods on hand. An ERP system with robust inventory management capabilities can help small manufacturers track inventory levels, generate automated reorder points, and optimize inventory turnover.

2. Production Planning and Scheduling: One of the most critical functions for small manufacturers is production planning and scheduling. An ERP system designed for small manufacturers should include tools for creating work orders, scheduling production tasks, and tracking progress in real-time. This functionality can help small manufacturers optimize production processes, reduce lead times, and improve overall efficiency.

3. Quality Control: Maintaining high-quality standards is essential for small manufacturers to meet customer expectations and comply with industry regulations. An ERP system with quality control features can help small manufacturers track quality metrics, conduct inspections, and implement corrective actions when issues arise. This functionality can help small manufacturers improve product quality and reduce defects.

4. Supply Chain Management: Small manufacturers often rely on a network of suppliers and partners to source raw materials and components. An ERP system with supply chain management capabilities can help small manufacturers streamline their procurement processes, track supplier performance, and manage relationships with vendors. This functionality can help small manufacturers reduce lead times, minimize stockouts, and enhance collaboration with suppliers.

5. Financial Management: Small manufacturers need to carefully manage their finances to remain profitable and sustainable. An ERP system with financial management features can help small manufacturers track expenses, generate accurate financial reports, and manage budgets. This functionality can help small manufacturers make informed decisions, identify cost-saving opportunities, and improve financial performance.

6. Reporting and Analytics: Small manufacturers need access to real-time data and insights to make informed decisions and drive continuous improvement. An ERP system with reporting and analytics capabilities can help small manufacturers analyze key performance indicators, monitor trends, and identify areas for improvement. This functionality can help small manufacturers optimize processes, reduce waste, and increase productivity.

In conclusion, small manufacturers can benefit from using ERP software that is tailored to their specific needs and challenges. Key features and functions such as inventory management, production planning, quality control, supply chain management, financial management, and reporting and analytics are essential for small manufacturers to optimize operations, improve efficiency, and drive growth.

Benefits of Implementing ERP in Small Manufacturing Businesses

ERP software can provide numerous benefits for small manufacturing businesses looking to streamline their processes and improve their overall efficiency. Here are some of the key advantages of implementing ERP in a small manufacturing setting:

1. Improved efficiency and productivity: One of the primary benefits of implementing ERP software in a small manufacturing business is the improvement in efficiency and productivity. By centralizing all of your business processes and data into a single system, you can eliminate the need for manual data entry and reduce the likelihood of errors. This can lead to faster production times, reduced lead times, and overall increased productivity for your business.

2. Better inventory management: Small manufacturing businesses often struggle with inventory management, leading to issues such as stockouts, overstocking, and inventory inaccuracies. ERP software can help streamline your inventory management processes by providing real-time visibility into your inventory levels, tracking inventory movements, and generating accurate forecasts based on demand trends. This can help you optimize your inventory levels, reduce carrying costs, and improve your overall profitability.

3. Enhanced decision-making capabilities: Another key benefit of implementing ERP in a small manufacturing business is the enhanced decision-making capabilities it provides. With ERP software, you can access real-time data and analytics on various aspects of your business, such as production schedules, inventory levels, sales trends, and financial performance. This information can help you make more informed decisions, identify areas for improvement, and seize new opportunities for growth. By having access to accurate and up-to-date information, you can make better strategic decisions that can drive your business forward.

4. Regulatory compliance: Small manufacturing businesses are often subject to various regulations and compliance requirements, such as quality standards, safety regulations, and environmental laws. Failure to comply with these regulations can result in hefty fines, legal liabilities, and reputational damage. ERP software can help small manufacturers maintain compliance by providing tools for tracking and reporting on regulatory requirements, ensuring that all necessary protocols are followed, and maintaining detailed records for audits and inspections.

5. Cost savings: Implementing ERP software in a small manufacturing business can also lead to cost savings in the long run. By streamlining your processes, reducing manual work, and eliminating inefficiencies, ERP can help you cut down on operational costs, improve resource utilization, and optimize your supply chain. Additionally, having accurate data and analytics at your fingertips can help you identify cost-saving opportunities, negotiate better terms with suppliers, and make more strategic decisions that can lower your overall expenses.

Overall, implementing ERP software in a small manufacturing business can provide a wide range of benefits, from improving efficiency and productivity to enhancing decision-making capabilities and ensuring regulatory compliance. By harnessing the power of ERP, small manufacturers can gain a competitive edge, drive growth, and achieve long-term success in a highly competitive industry.

Considerations for Selecting the Right ERP Software for Small Manufacturers

When it comes to choosing an ERP software for small manufacturers, there are several key considerations that need to be taken into account in order to ensure that the system meets the specific needs of the business. One important factor to consider is the size of the company and its budget. Small manufacturers may not have the resources to invest in a large, complex ERP system, so finding a solution that is affordable and scalable is essential.

Another consideration is the specific requirements of the manufacturing process. Some ERP systems are designed for specific industries or types of manufacturing, so it is important to choose a system that is tailored to the needs of the business. Considering the number of users who will be accessing the system and the level of customization required is also important when selecting an ERP solution.

Integration with existing systems is another key consideration when selecting an ERP software for small manufacturers. The system should be able to seamlessly integrate with other software and hardware that the company already uses, in order to avoid any disruptions to the workflow. Compatibility with mobile devices and cloud-based solutions can also be beneficial for small manufacturers who need to access their data on-the-go.

Additionally, ease of use and training requirements should be taken into consideration when selecting an ERP software for small manufacturers. The system should be intuitive and user-friendly, with a minimal learning curve for employees. Training and support options should also be available to help employees get up to speed quickly and efficiently.

Lastly, considering the future growth and scalability of the business is important when selecting an ERP software for small manufacturers. The chosen system should be able to grow with the company and adapt to changing needs over time. Scalability options, such as the ability to add new users or modules, should be available to accommodate future growth.

By taking these key considerations into account when selecting an ERP software for small manufacturers, businesses can ensure that they choose a system that meets their specific needs and helps streamline their manufacturing processes.

Case Studies of Successful Small Manufacturing ERP Implementations

Implementing an ERP system for small manufacturing businesses can drastically improve efficiency, productivity, and overall business operations. Here are some real-world examples of successful ERP implementations in small manufacturing companies:

1. XYZ Company: XYZ Company is a small manufacturing firm that specializes in creating customized metal parts for various industries. Before implementing an ERP system, they were struggling to keep track of inventory, manage orders, and coordinate production schedules. After implementing a small manufacturing ERP software, they were able to streamline their operations, reduce lead times, and improve customer satisfaction. The ERP system allowed XYZ Company to track inventory levels in real-time, automate order processing, and optimize production schedules. As a result, they were able to increase production output by 20% and reduce lead times by 30%.

2. ABC Manufacturing: ABC Manufacturing is a family-owned business that produces high-quality textiles for the fashion industry. With a growing customer base and increasing demand, they needed a solution to manage their complex supply chain and production processes. By implementing a small manufacturing ERP software, ABC Manufacturing was able to achieve better visibility into their supply chain, improve production planning, and enhance inventory management. The ERP system enabled them to track raw materials from procurement to production, optimize production schedules based on demand forecasts, and reduce wastage. As a result, ABC Manufacturing was able to reduce overhead costs by 15% and increase on-time delivery rates by 25%.

3. LMN Industries: LMN Industries is a small electronics manufacturing company that was facing challenges with inventory control, order tracking, and quality management. By implementing a small manufacturing ERP software, they were able to address these issues and improve their overall efficiency. The ERP system allowed LMN Industries to track raw materials and finished goods in real-time, automate quality control processes, and generate detailed reports for analysis. With better inventory control and streamlined processes, LMN Industries was able to reduce stockouts by 40%, improve order accuracy by 20%, and achieve a 10% increase in production efficiency.

4. PQR Manufacturing: PQR Manufacturing is a small automotive parts manufacturer that was struggling to meet the demands of their customers due to outdated processes and lack of visibility into their operations. By implementing a small manufacturing ERP software, they were able to modernize their operations and improve their competitive edge. The ERP system enabled PQR Manufacturing to automate order processing, optimize production schedules, and enhance quality control measures. With improved visibility into their supply chain and streamlined processes, PQR Manufacturing was able to reduce lead times by 25%, increase production output by 15%, and achieve a 30% reduction in production costs.

5. EFG Enterprises: EFG Enterprises is a small food processing company that was looking to scale their operations and expand into new markets. By implementing a small manufacturing ERP software, they were able to transform their business and position themselves for growth. The ERP system enabled EFG Enterprises to streamline their production processes, improve inventory control, and enhance quality assurance measures. With better resource planning and automated workflows, EFG Enterprises was able to increase production capacity by 50%, reduce waste by 40%, and launch new product lines successfully. This ERP implementation was crucial in helping EFG Enterprises achieve their expansion goals and gain a competitive edge in the market.